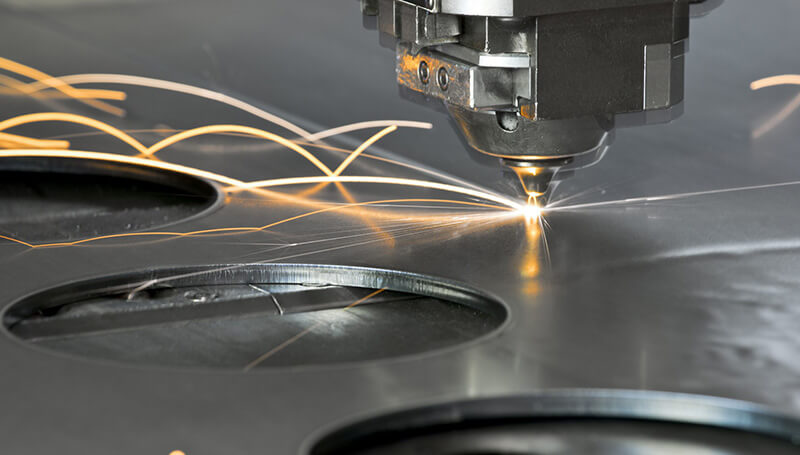

CNC Laser Cutting Machine

A CNC laser cutting machine is a computer-controlled system designed to cut a variety of materials with high precision. Using powerful laser beams directed by CNC programming, it eliminates the need for manual cutting tools and delivers exceptional accuracy even in complex designs.

These machines are widely used for intricate designs and mass production tasks, making them an essential part of modern industrial manufacturing. Whether it’s sheet metal, plastic, or acrylic, the CNC laser cutting machine ensures speed, consistency, and quality.

Key Benefits of CNC Laser Cutting Machine

1. Unmatched Precision

The core advantage of a CNC laser cutting machine is its ability to deliver extremely precise cuts. Its computer-controlled nature minimizes errors, allowing industries to achieve tight tolerances for high-quality components.

2. Versatility Across Materials

From metals to non-metals, these machines work seamlessly on various surfaces. For thicker materials, the fiber laser cutting machine is ideal, whereas delicate jobs are often better suited for a CO2 laser machine.

3. Efficiency in Production

Speed and reduced waste are vital in manufacturing. A CNC laser cutting machine optimizes both, cutting faster than traditional methods while ensuring minimal material loss.

Fiber Laser Cutting Machine: The Powerhouse of Modern Cutting

The fiber laser cutting machine stands out for its ability to cut reflective metals like copper, brass, and aluminum with ease. Its high-energy efficiency and low maintenance make it the preferred choice for industries that require high-volume metal cutting.

This type of machine is equipped with fiber-optic-delivered lasers, enabling faster cutting speeds and superior precision. Many manufacturers rely on fiber technology because it provides cost-effective solutions without compromising quality.

CO2 Laser Machine: Perfect for Non-Metal Applications

While fiber lasers dominate metal cutting, the CO2 laser machine remains invaluable for non-metal materials like wood, glass, and plastics. With its versatile beam, it delivers smooth edges and intricate details on delicate surfaces.

These machines are commonly used in signage, engraving, and decorative industries. Integrating a CO2 laser machine into production ensures flawless results in applications where finesse is more important than sheer power.

Metal Laser Cutting Machine: Redefining Fabrication

When it comes to industrial-grade fabrication, a metal laser cutting machine plays an essential role. Capable of handling various metals such as steel, titanium, and alloys, it ensures rapid production without compromising durability.

By combining this technology with CNC programming, industries achieve efficient workflows. The metal laser cutting machine allows even complex components to be produced with speed, accuracy, and reduced operational costs.

Why Choose a CNC Laser Cutting Machine for Metal Fabrication?

When dealing specifically with metal materials, a laser cutting machine for metal is indispensable. It delivers clean cuts, eliminates the need for post-processing, and significantly improves manufacturing efficiency.

By using a CNC laser cutting machine, industries benefit from:

-

Minimal human error through automated programming.

-

Faster turnaround for bulk orders.

-

Superior quality suitable for high-demand sectors like aerospace and automotive.

Applications of CNC Laser Cutting Machine

Industrial Manufacturing

In heavy industries, the CNC laser cutting machine is vital for creating strong, durable components quickly.

Automotive Industry

Precision parts such as gears, panels, and brackets are crafted using fiber laser cutting machines to ensure safety and performance.

Architectural Designs

From intricate metal screens to decorative panels, the laser cutting machine for metal allows designers to turn creative visions into reality.

CNC Laser Cutting Machine vs Traditional Cutting Methods

Traditional cutting methods, like manual sawing or drilling, lack the precision and speed offered by modern CNC laser cutting machines. With automation and software integration, manufacturers reduce errors, improve efficiency, and meet large-scale demands effortlessly.

Additionally, using tools like the CO2 laser machine or fiber laser cutting machine eliminates the wear-and-tear associated with manual tools, leading to lower long-term costs.

Future of CNC Laser Cutting Machine Technology

The CNC laser cutting machine industry continues to evolve with advancements in automation, AI integration, and enhanced laser power. Future models are expected to be faster, smarter, and even more energy-efficient, solidifying their place in high-tech manufacturing.

Conclusion

In the ever-growing manufacturing world, investing in a CNC laser cutting machine is no longer optional but necessary. With tools like the fiber laser cutting machine, CO2 laser machine, and specialized laser cutting machine for metal, businesses achieve unparalleled efficiency and precision.

For industries seeking reliable, scalable, and high-quality production, adopting a CNC laser cutting machine paves the way for consistent success and innovation in fabrication processes.