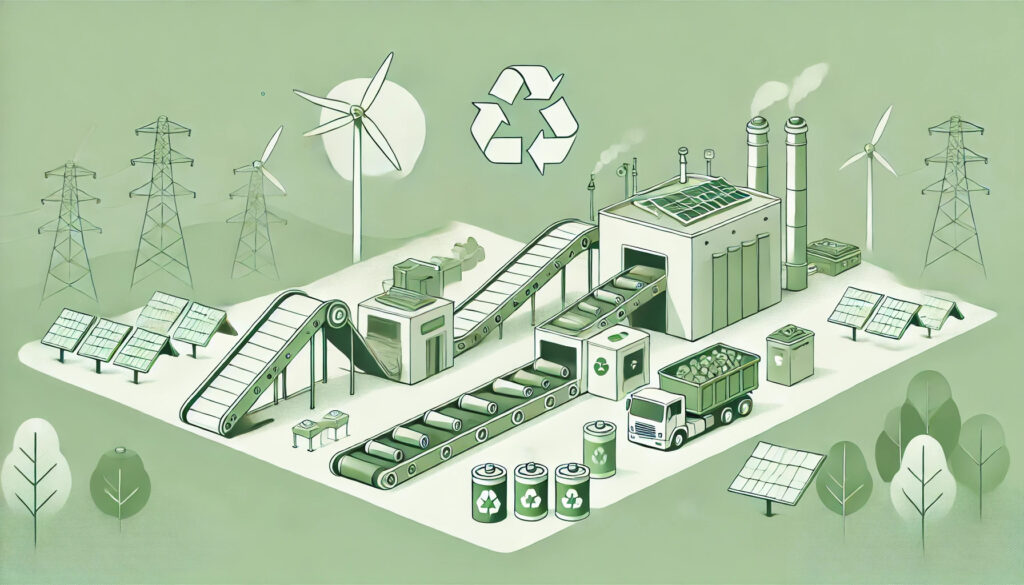

India’s push toward electric mobility and renewable energy has fueled a surge in battery usage—from EVs to solar storage systems. However, this progress comes with a hidden cost: mounting battery waste. Discarded lithium-ion, lead-acid, and nickel-based batteries leak toxic metals like lead, cadmium, and mercury, contaminating ecosystems and endangering public health. EPR (Extended Producer Responsibility) for battery waste management offers a solution, turning regulatory compliance into a catalyst for sustainability and business innovation.

EPR for battery waste management mandates producers, importers, and recyclers to manage the entire lifecycle of batteries, from collection to recycling. Governed by India’s Battery Waste Management Rules, 2022, this framework ensures businesses take accountability for their products, reducing reliance on unsafe informal recycling practices. Beyond avoiding penalties, compliance unlocks opportunities to recover valuable materials like lithium, cobalt, and graphite, which can be reused in manufacturing, lowering raw material costs and supporting a circular economy.

Adopting EPR authorization for battery waste delivers multifaceted benefits. Environmentally, it prevents hazardous substances from polluting soil and groundwater. Economically, it reduces dependency on costly mining by reclaiming critical metals. Strategically, it enhances brand reputation as consumers and investors increasingly favor companies committed to ESG (Environmental, Social, Governance) principles. Additionally, compliance with CPCB (Central Pollution Control Board) guidelines ensures operational continuity and shields businesses from legal risks.

Implementing EPR involves a structured approach. Begin by assessing your organization’s battery waste footprint, factoring in sales volume and battery types—portable, automotive, or industrial. Next, design a collection network by partnering with authorized recyclers or establishing drop-off points for consumers. Submit a detailed EPR plan to the CPCB, outlining recycling targets, collection logistics, and partnerships. Upon approval, the EPR certification for battery waste is granted, valid for five years. Regular monitoring and annual reporting ensure adherence to evolving standards.

As India accelerates its EV and clean energy ambitions, battery waste is poised to grow exponentially. Proactive adoption of EPR for battery waste management positions businesses as industry leaders, ready to meet future regulatory demands and capitalize on recycling’s economic potential. By transforming waste into resources, companies can drive cost efficiency, foster innovation, and align with global sustainability goals.

EPR for battery waste is more than a compliance checkbox it’s a strategic investment in a greener, more profitable future. Embrace it today to turn environmental responsibility into a competitive edge.