The discovery of food basket liner raw material is considered a crucial process when a business wishes to maintain quality, hygiene, and appearance in the foodservice industry. The selection of the appropriate raw material directly influences the life of the liners, the look and usage of the liners in restaurants, fast-food joints, and the catering industry. Quality liners ensure customer satisfaction in addition to reducing waste and improving food standards. Whether it is texture or printability, everything counts when sourcing materials. Taking time and effort to select the right material will help ensure food basket linens are utilized to meet operational and branding requirements efficiently to deliver a professional and polished service.

Knowledge of Material Type

Food basket liners come in all sorts of liner materials, including kraft, wax-coated, and greaseproof paper. Both types are used to achieve a particular task, be it to absorb grease, keep a print dry, or hold a printed pattern. Understanding the variations enables the restaurants to select the appropriate liner for the menu items. The selection of suitable material also ensures that the liner will be favorable to the serving conditions and bring hygiene and completeness to the food.

Supplier Analysis Plans

Food basket liners need to be sourced from trusted suppliers. Vendors are assessed based on manufacturing capabilities, consistency of quality, and food-grade standards. Other documentation of safety and material specifications is also sourced by reputable suppliers. It is possible to conduct trials before bulk purchases to recognize the best partners. Selecting suppliers with a high level of reliability has been in ensuring that the liners are delivered on time, minimizing operational risks, and ensuring the liners satisfy performance and branding expectations.

Benefits of Wholesale Options

The food liners sheets are inexpensive when used in large quantities. Dining and catering companies take advantage of bulk buying by keeping the unit cost low and making all the orders the same. It is also possible to have better quality, a predictable supply, and a manageable inventory under wholesale arrangements. With bulk purchases, a company can ensure a steady stream of quality liners without having to regularly run purchases, sustaining operations during the day and special events.

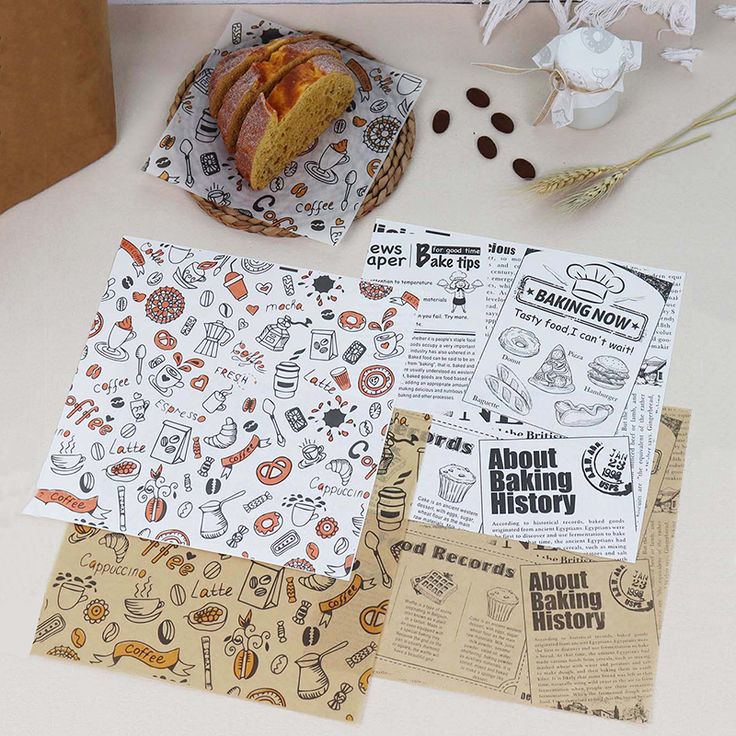

Customization Opportunities

The use of custom food basket liners allows companies to add logos, patterns, or a certain brand color. Customized designs can improve dining experience, brand identity, and provide a memorable experience to the customer. Flexography and digital printing are printing methods that enable rich colourful graphics on liners. This is because specialists can change liners to suit different menu items, without any effect on their functionality or hygiene.

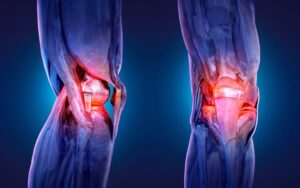

Fast-Food Compatibility

The fast food basket liners should resist grease and moisture, as well as be resistant to high handling frequency. Choosing fast food basket liners that combine durability and cost-efficiency will provide the highest possible performance in high-traffic settings. Captures leakages, keeps presentations, and eases the workload on the staff. Durable liners help in satisfying customers, as these ensure food is stored and looks good until it gets delivered or is eaten in a restaurant.

Printed Designs Impact

Communication with the help of printing the food basket liner will enable the food basket liner to appear attractive, and it can also adopt marketing approaches. When brand logos or ornamental designs are used, they contribute to enhancing brand presence whenever an order is issued. Good prints not only remain transparent when exposed to heat or grease, but they also enable the garments to be washed without damaging them. Printed designs can assist restaurants and cafes in creating a memorable experience when eating, making the road to the table more interesting and leading to sharing on social media, which, in turn, leads to brand recognition and brand loyalty.

Sheet Versatility Benefits

Food liner sheets offer cut and set flexibility with different sizes and shapes of baskets. Sheets are easy to handle, can be easily portioned, and can be replaced very quickly during service. Quality checks are in place so that a defective batch does not reach the restaurants, protecting customer experience and brand. Sheets make the work in each kitchen easier, allow for maintaining consistency when presenting food, and reduce operational waste, which contributes to more efficient services.

Ensuring Quality Control

All quality parameters in the production of basket liners include strict testing of thickness, resistance to grease, print sharpness, and durability. The quality checks ensure that batches with defects do not reach restaurants, safeguarding both customer experience and brand reputation. Custom paper wholesale clear specifications between suppliers and frequent inspection combine to assure the continued attainment of professional, safe, and attractive presentation of products through liners, which consistently meet operational and aesthetic specifications.

Conclusion

The discovery of raw materials that could make the food basket liner is necessary whenever a restaurant/foodservice business intends to integrate functionality, cleanliness, and branding. Starting with the choice of the appropriate type of paper, through the assessment of the supplier, to the possibility of customization, the cycle helps to achieve high-quality liners that correspond to operational requirements. The addition of wholesale and printed possibilities can improve efficiency, brand visibility, and sheet versatility, allowing many service styles. Businesses can offer reliable, attractive, and consistent liners by focusing on quality control and proper selection of materials. Packaging is only part of sourcing the raw material; sourcing the raw materials is also a strategic investment in customer satisfaction and professionalism.