Full Vehicle End of Line Test

In the fast-paced world of vehicle manufacturing, speed and accuracy are everything. One of the most crucial steps in ensuring a high-quality product is the Full Vehicle End of Line Test. This test is a final check to verify that every component of a vehicle works as it should, ensuring safety, reliability, and performance before the car hits the road.

As the demand for faster production times and higher-quality vehicles increases, automating this process has become essential. Automating the Full Vehicle End of Line Test can significantly enhance the speed and accuracy of vehicle production, reducing errors and ensuring a more efficient workflow. If you’re interested in learning more about automating this critical process, check out Full Vehicle End of Line Test solutions today.

What Is the Full Vehicle End of Line Test?

The Full Vehicle End of Line Test is the final phase in the vehicle production process. It involves checking various systems of the vehicle, including engine performance, brakes, electrical systems, safety features, and more. The goal is to ensure the vehicle meets all regulatory standards and quality requirements before it leaves the production line.

This process typically involves several manual steps, such as visual inspections, physical tests, and functional checks. However, the complexity and time-consuming nature of these tasks are prompting manufacturers to automate them to improve production efficiency.

Why Automate the Full Vehicle End of Line Test?

Automating the Full Vehicle End of Line Test brings numerous advantages to manufacturers, from increased speed to enhanced accuracy. Let’s explore some key reasons why automation is crucial:

1. Increased Speed and Throughput

Manual testing is time-consuming and can slow down the entire production process. Automated systems, on the other hand, perform tasks much faster without sacrificing quality. By speeding up the testing process, manufacturers can significantly increase throughput, producing more vehicles in less time.

2. Higher Accuracy and Consistency

Humans can be prone to errors, especially when performing repetitive tasks. Automated testing systems ensure each test is conducted with the same level of precision, improving consistency and reducing the likelihood of mistakes. This leads to fewer faulty vehicles and fewer costly recalls.

3. Improved Resource Allocation

By automating testing, manufacturers can allocate human resources to more complex tasks that require problem-solving and creativity. This helps optimize labor utilization, ensuring that employees can focus on tasks that truly add value to the production process.

Key Benefits of Automating the End of Line Test

Automating the Full Vehicle End of Line Test offers several key benefits that go beyond just speed and accuracy:

1. Cost Reduction

Automated testing systems can reduce the need for manual labor, which directly lowers labor costs. Additionally, by minimizing the chances of defects and recalls, automation helps save money in the long run.

2. Real-Time Monitoring and Data Collection

Modern automated systems can monitor vehicle performance in real-time and collect detailed data on every test conducted. This data can be analyzed to identify trends, predict potential issues, and optimize the production process, leading to more informed decision-making.

3. Reduced Downtime

Automated testing systems often come with self-diagnostic features that identify issues early, reducing the likelihood of unexpected breakdowns. This means less downtime for the testing phase and more time spent on actual production.

How Automation Enhances Testing Precision

Precision is critical in the Full Vehicle End of Line Test. Automation helps improve precision in several ways:

1. Consistent Test Conditions

Automated testing systems can ensure that all vehicles are subjected to the same conditions during the testing process. Whether it’s engine performance, brake testing, or safety feature validation, automation eliminates variations caused by human error.

2. Detailed Diagnostics

Advanced automated systems can conduct highly detailed diagnostics on a vehicle’s performance, identifying even the smallest inconsistencies that might go unnoticed in manual testing. This detailed information helps manufacturers make more informed decisions and ensures the highest quality standards.

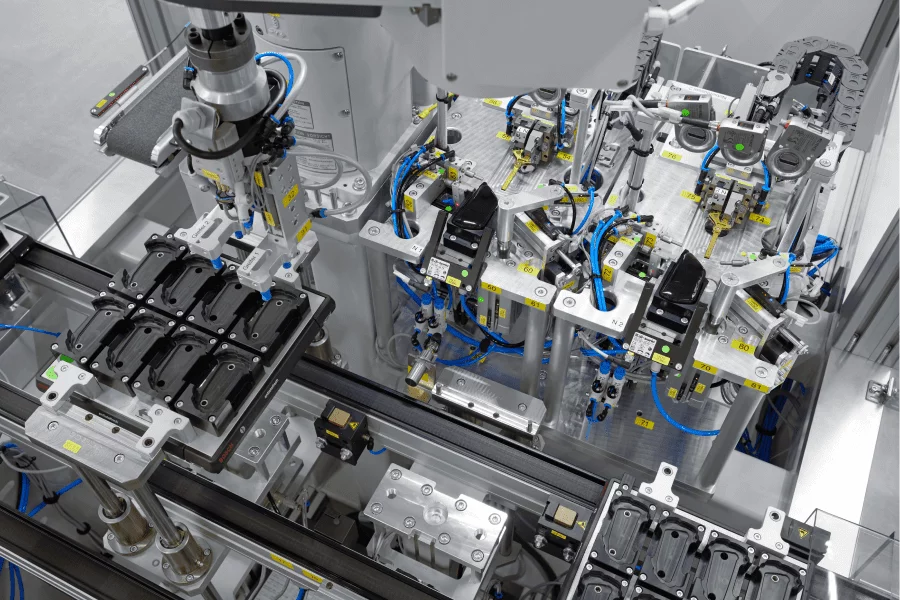

How Automated Presses Help in the End of Line Test

One essential component of automating the Full Vehicle End of Line Test is using automated presses, which are used to simulate conditions like pressure and load. These presses ensure that all mechanical components function as expected under varying conditions. Here’s how they contribute to the testing process:

-

Simulating real-world pressures: Automated presses can mimic the weight and force a vehicle’s components will experience on the road, helping identify any weak points.

-

Testing for component durability: Automated presses help test how parts, such as the engine and suspension, perform under heavy loads.

-

Ensuring proper alignment: These systems can also ensure that all parts are correctly aligned and securely fastened, avoiding any potential issues that could arise during real-world use.

Automating this part of the testing process not only improves speed but also increases the reliability of the final product.

Integration with Other Automation Systems

The Full Vehicle End of Line Test doesn’t operate in isolation. It integrates with other automation systems across the manufacturing process. Here’s how the entire system works together:

1. Automated Assembly Lines

Assembly lines have already been automated in many industries, and they play a critical role in the vehicle production process. Automated assembly lines ensure that parts are assembled with precision and efficiency, setting the stage for the end of line test.

2. Robotic Testing Systems

Robotic systems are used to conduct several tests during the end-of-line process, such as engine testing, component testing, and even visual inspections. These robots work in conjunction with other automated systems to perform tasks with speed and accuracy.

3. AI and Machine Learning

AI and machine learning algorithms can analyze data collected during the Full Vehicle End of Line Test to detect anomalies or patterns that could indicate potential issues in the vehicle. This predictive analysis helps manufacturers address problems before they become critical.

Challenges in Automating the End of Line Test

While automation offers many benefits, it also comes with its own set of challenges:

1. High Initial Investment

The upfront cost of setting up automated systems can be significant. However, the long-term savings in labor, time, and quality control typically outweigh the initial investment.

2. Complexity in Integration

Integrating automated systems with existing production lines and machinery can be complex. It requires careful planning and coordination to ensure that all systems work together seamlessly.

3. Maintenance and Support

Automated systems require regular maintenance to ensure optimal performance. Manufacturers need to invest in training and support to keep the systems running smoothly.

The Future of Automated Vehicle Testing

The future of Full Vehicle End of Line Testing looks bright, with even more advanced technologies on the horizon:

1. Enhanced Robotics

Robotic systems are expected to become even more advanced, capable of performing more complex tasks with greater flexibility and precision.

2. 3D Imaging and Virtual Testing

3D imaging technology and virtual testing systems will allow manufacturers to test a vehicle’s performance in simulated environments, reducing the need for physical prototypes.

3. Internet of Things (IoT) Integration

IoT devices will play an even larger role in vehicle testing by enabling real-time data collection, analysis, and communication across all stages of production. This integration will help optimize production efficiency and quality.

Conclusion: Automating the Full Vehicle End of Line Test for Greater Efficiency

The benefits of automating the Full Vehicle End of Line Test are clear. By enhancing precision, reducing errors, improving efficiency, and providing valuable real-time data, automation is helping manufacturers produce high-quality vehicles faster and more cost-effectively. Although there are challenges in implementing automation, the long-term gains far outweigh the initial investment.

If you’re looking to enhance your manufacturing processes, automating your vehicle testing system is a step in the right direction. Explore more about automating the Full Vehicle End of Line Test and get started today.