In a world driven by innovation and speed, traditional manufacturing methods are quickly being reimagined. At the heart of this transformation is metal 3D printing, a cutting-edge technology that’s reshaping how industries design, prototype, and produce custom components.

From aerospace and automotive to healthcare and industrial design, Metal 3D Printing is no longer a futuristic concept—it’s the present, and it’s rapidly becoming the go-to solution for creating complex, high-performance parts with unmatched precision.

What Is Metal 3D Printing?

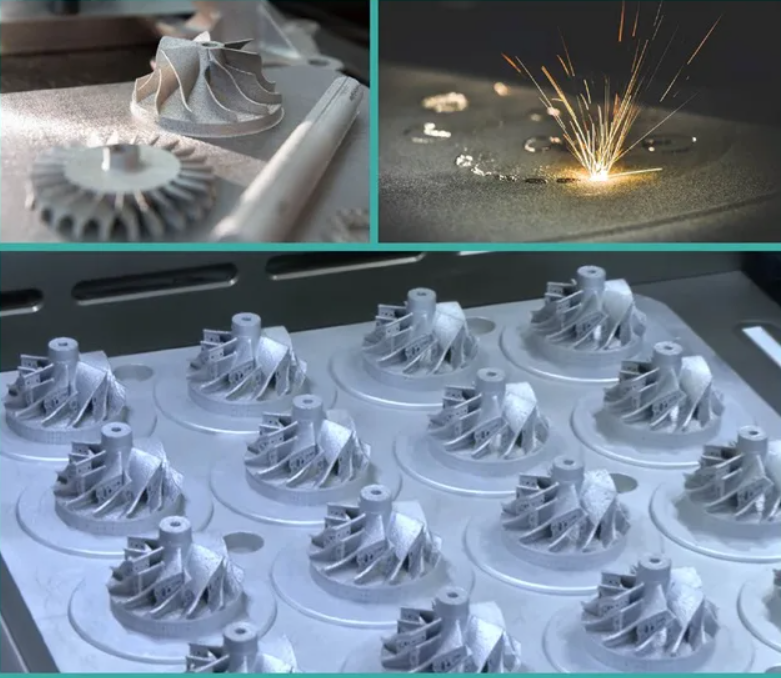

Metal 3D printing, also known as additive manufacturing, is the process of creating three-dimensional metal objects directly from a digital design. Unlike traditional subtractive manufacturing methods that cut away material, 3D printing builds parts layer by layer, reducing waste and allowing for more intricate geometries.

Common Metal 3D Printing Techniques:

-

Direct Metal Laser Sintering (DMLS)

-

Selective Laser Melting (SLM)

-

Electron Beam Melting (EBM)

-

Binder Jetting

These methods use materials like titanium, stainless steel, aluminum, and nickel alloys, making them ideal for parts that require durability, corrosion resistance, and heat tolerance.

Why Metal 3D Printing Is Transforming Custom Manufacturing

1. Design Freedom Without Compromise

One of the biggest advantages of metal 3D printing is the ability to manufacture parts that are traditionally difficult—or impossible—to create using conventional methods. Complex lattice structures, internal channels, and optimized lightweight designs are now fully achievable.

Engineers and designers are no longer constrained by tool access or mold limitations. If it can be imagined, it can be printed.

2. Rapid Prototyping and Faster Time-to-Market

Speed matters—especially when iterating on prototypes or getting a product to market. Metal 3D printing allows companies to go from CAD file to functional part in a fraction of the time compared to machining or casting.

Quick turnaround times mean faster innovation, better product development cycles, and a competitive edge in fast-paced industries.

3. Cost-Effective for Low-Volume Production

Traditional manufacturing methods often require expensive tooling, which only makes sense for high-volume runs. Metal 3D printing services, on the other hand, are perfect for small-batch or custom parts because they eliminate the need for tooling altogether.

This makes it ideal for:

-

Custom medical implants

-

Replacement parts for discontinued machinery

-

Specialized aerospace components

-

Performance automotive upgrades

4. Material Efficiency and Sustainability

By building parts layer by layer, metal 3D printing significantly reduces material waste. This not only lowers costs but also contributes to more sustainable manufacturing practices—a priority for modern industries.

Some processes even allow for powder recycling, further improving eco-efficiency.

Industries Driving the Future with Metal 3D Printing

Aerospace

The aerospace industry was one of the first to adopt metal 3D printing due to its need for lightweight, high-strength components. Parts like turbine blades, fuel nozzles, and structural supports are now commonly 3D printed to reduce weight and improve performance.

Automotive

From Formula 1 racing to luxury vehicles, carmakers are using 3D printing to create performance parts with complex geometries that reduce drag and increase efficiency. Custom exhaust manifolds, engine components, and heat exchangers are just the beginning.

Healthcare

In the medical field, personalization is key. Metal 3D printing is enabling the creation of patient-specific implants, surgical instruments, and even dental prosthetics with precise anatomical fit and improved outcomes.

Industrial and Tooling Applications

Industrial manufacturers are using metal 3D printing to produce jigs, fixtures, and end-use parts faster and more affordably than ever before—helping reduce lead times and enhance operational agility.

The Role of Professional Metal 3D Printing Services

While desktop 3D printers are gaining popularity, creating reliable, high-quality metal parts still requires specialized equipment, expertise, and post-processing capabilities.

That’s where metal 3D printing services come in. These providers offer:

-

Access to industrial-grade printers

-

A range of certified metal powders

-

Design optimization support

-

Heat treatment, CNC finishing, and quality inspection

Partnering with an experienced service provider ensures you get parts that meet mechanical, dimensional, and safety standards—whether for prototyping or production.

What’s Next for Metal 3D Printing?

As technology advances, we’re seeing more cost-effective printers, faster build speeds, and expanded material options. The integration of AI and simulation tools is also helping engineers optimize part performance before a single layer is printed.

In the near future, expect:

-

More on-demand manufacturing networks

-

Fully automated print-to-product workflows

-

Expansion into consumer goods and electronics

Final Thoughts: The Custom Future Is Now

The future of manufacturing is custom, and metal 3D printing is at the forefront of this shift. Its ability to deliver lightweight, durable, and precisely engineered parts is empowering designers, engineers, and businesses to create like never before.

Whether you’re developing a new product, solving a supply chain challenge, or looking to replace a legacy part, metal 3D printing offers an efficient, scalable, and sustainable solution.

Explore the possibilities of metal 3D printing today and step into the future of custom part production.